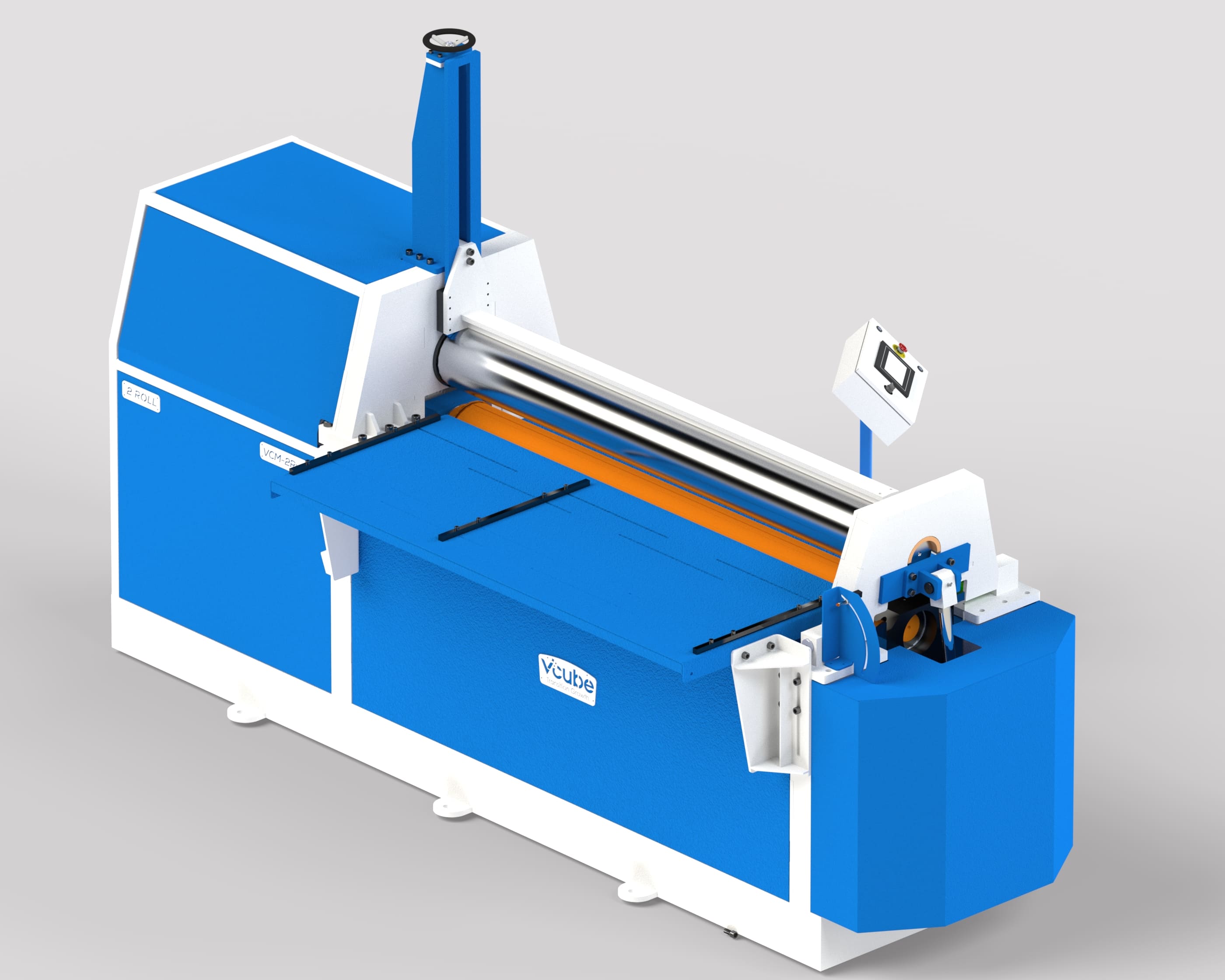

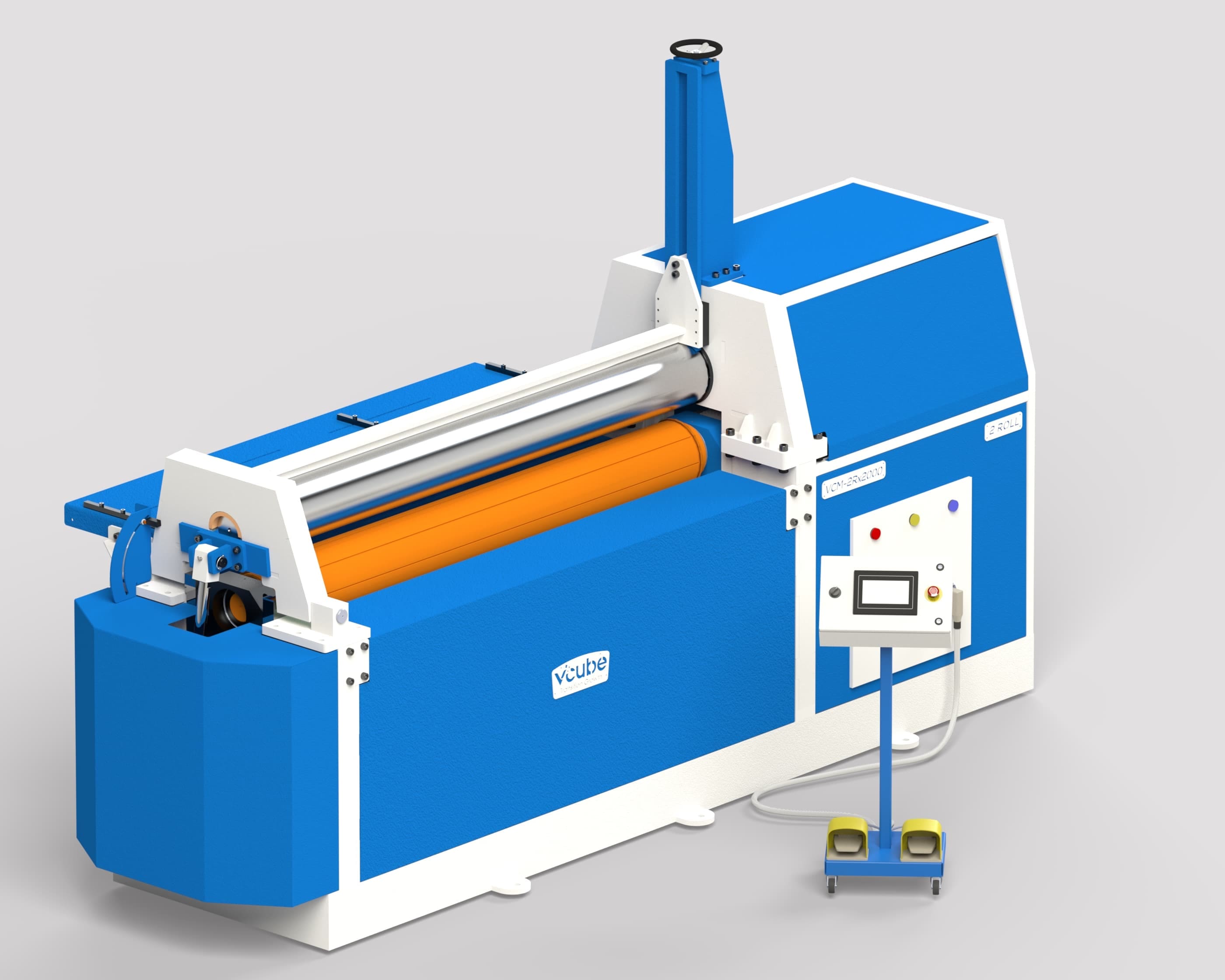

Sheet Rooll Machine ( VCM/2RHP2000)

The VCM/2RHP2000 is a high-performance 2-roll horizontal sheet rolling machine designed for bending stainless steel (SS304 and higher) up to 2mm thick. It features a 2100mm working length and a minimum bending diameter of 120mm. The machine is PLC-controlled, with a fixed top roller and a hydraulically adjustable bottom roller made of EN8 with polyurethane coating. Powered by a 10 HP motor and 5 HP hydraulic pack, it includes VFD speed control, Siemens/L&T electricals, and safety sensors. Manual sheet feeding and removal are supported, and the rolling cycle takes 40–60 seconds. It weighs approximately 2 tons and ensures efficient, precise operation.

Key areas include quality control, customer satisfaction, employee involvement, and process optimization. Through TQM, we target higher consistency, reduced defects, and enhanced customer satisfaction, leading to better product reliability, reduced operational costs, and a stronger competitive position in the market.

| 2-Roll Sheet Roiling Machine ( VCM/2RHP2000) | ||

|---|---|---|

| SPECIFICATION | REMARKS | |

| Model No. | VCM/2RHP2000 | |

| Version | 2-Roll | |

| Type | Horizontal - PLC Controlled | |

| Machine Dimensions (L×B×H) | 3200mm × 1500mm × 1700mm (Exact size will be finalized after foundation layout) |

|

| Working Length | 2100mm | |

| Minimum Bending Diameter | 120mm | |

| Maximum Thickness | 2mm SS304 & higher grades only | |

| Top Roller | Custom as per product drawing | |

| Bottom Roller | 300mm EN8 Shaft with 35mm thick Polyurethane Rubber | |

| Main Drive | 10 HP Motor with Inline Helical Gearbox | |

| Hydraulic Power Pack | 5 HP | |

| Hydraulic Valves |

Pressure Relief Valve – Poly Hydron Check Valve – Poly Hydron Solenoid Valve – Yuken Flow Control Valve – Yuken |

|

| Power Supply | 415V, 3 Phase, 50 Hz, 4-Wire System | |

| Rolling Speed | Adjustable with VFD Support | |

| Electrical Parts | Siemens / L&T Make | |

| Safety Sensors | Included; Sensor Wiring in Client’s Scope | |

| End Dropper | Hydraulic | |

| Sheet Feeding | Manual | |

| Component Remover | Manual | |

| Hydraulic Tank Capacity | 100 Litres | |

| Rolling Operation | Top roller fixed; Bottom roller moves hydraulically | |

| Feeding Table | Movable feeding table included | |

| Control Panel | PLC Program with Pedal Operation | |

| Approx. Machine Weight | 2000 Kg / 2.0 Ton | |

| Component Cycle Time | Approx. 40–60 seconds depending on length and thickness | |