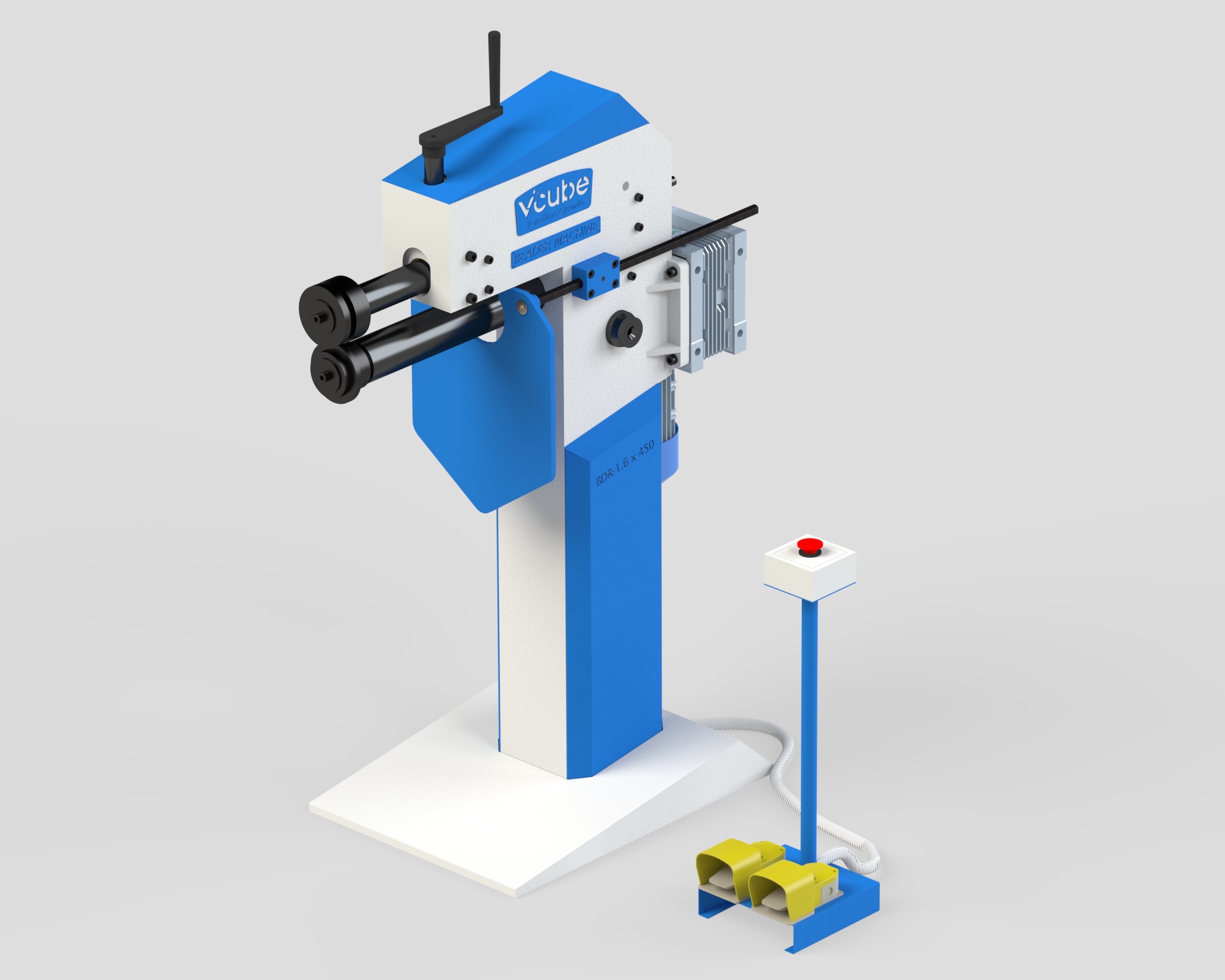

Beader Machine

The VCM/1.6x400is a compact and efficient pipe bending machine built for precise and rapid bending operations. It is powered by a 1 HP, 1440 RPM motor coupled with a worm gear box, ensuring smooth and controlled performance. Designed to deliver quick output, the machine completes each 90° bend in just 3 to 5 seconds, making it ideal for high-throughput environments. The VCM/208B variant is equipped with an inline helical gear box for enhanced torque and reliability. With a compact footprint of 900 mm × 600 mm × 1000 mm and a manageable weight of 275 kg, the VCM-20BB offers a space-saving solution without compromising on performance. This model is well-suited for small to medium-scale operations requiring speed, accuracy, and ease of use. It is an excellent choice for workshops and fabrication units seeking dependable bending capabilities in a compact form factor.

| Beader Machine | ||

|---|---|---|

| SPECIFICATION | REMARKS | |

| Model No. | VCM BR/1.6x400 | |

| Version | 2-Roll | |

| Type | Vertical - Manual | |

| Machine Dimensions (L×B×H) | 1200mm × 500mm × 1200mm (Exact size will be finalized after foundation layout) |

|

| Working Depth | 400mm | |

| Minimum Bending Diameter | 60mm | |

| Maximum Thickness | 1.6 mm ms & higher grades only | |

| Top Roller | Custom as per product drawing | |

| Bottom Roller | 50mm EN8 Shaft | |

| Main Drive | 1 HP Motor with Worm GearBox | |

| Power Supply | 415V, 3 Phase, 50 Hz, 4-Wire System | |

| Rolling Speed | Fixed | |

| Electrical Parts | Siemens / L&T Make | |

| Safety Sensors | Included; Sensor Wiring in Client’s Scope | |

| End Dropper | Manual | |

| Sheet Feeding | Manual | |

| Component Remover | Manual | |

| Rolling Operation | Bottom roller fixed; Top roller moves Manually | |

| Control Panel | Push Button Switches with Pedal Operation | |

| Approx. Machine Weight | 120 Kg | |

| Component Cycle Time | Approx. 40–60 seconds depending on length and thickness | |