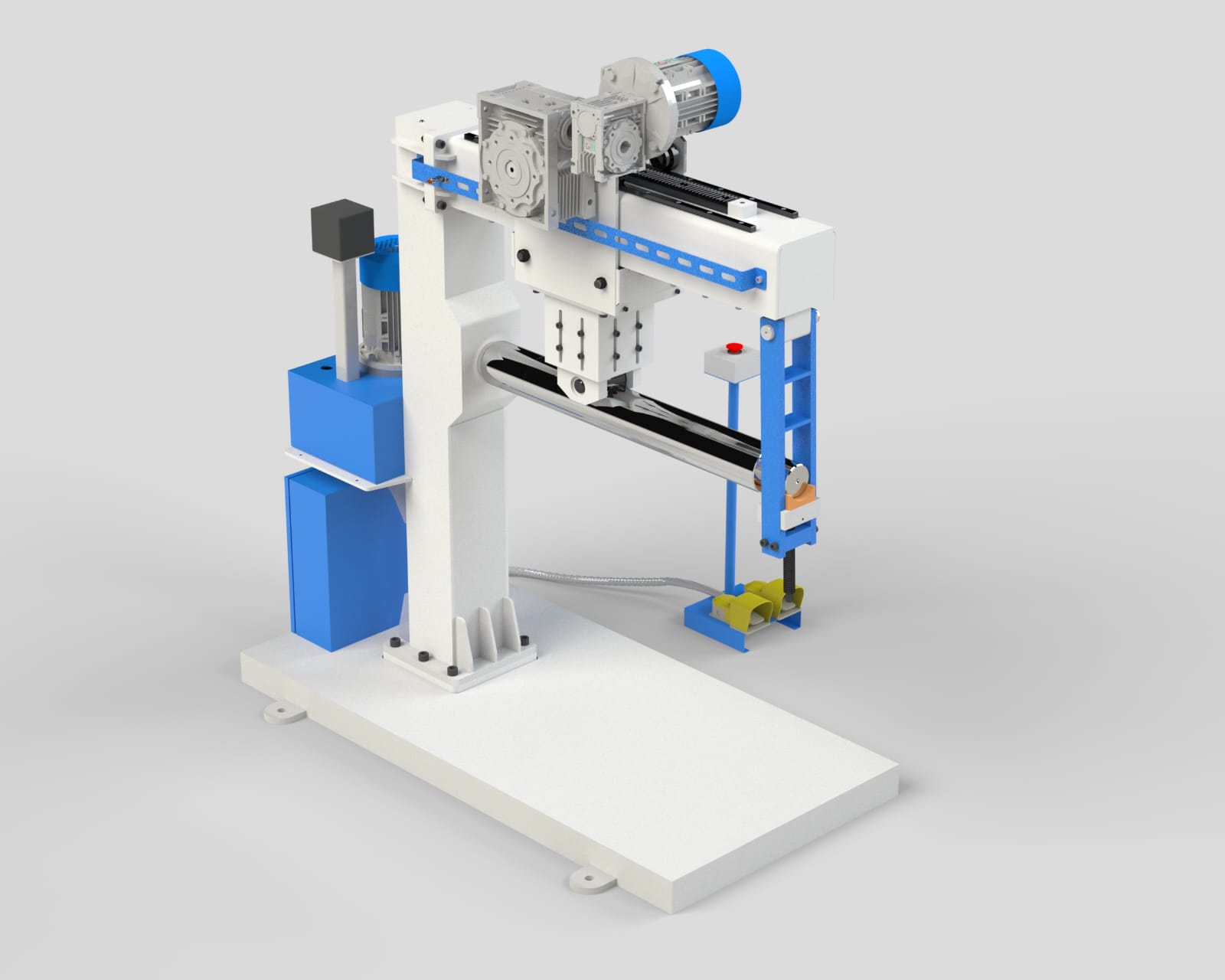

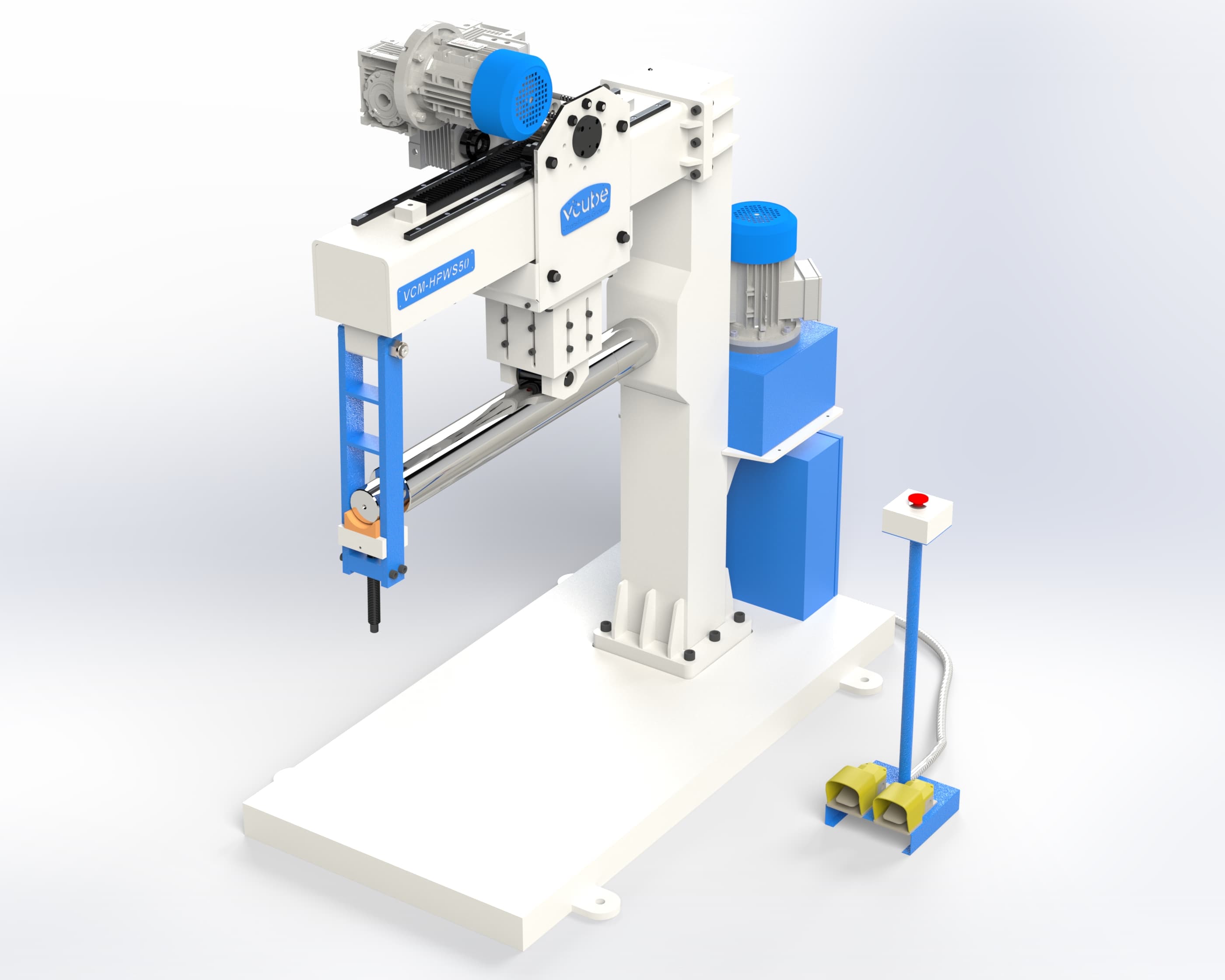

Weld Planishing MachineVCM / WPM 2x500

The VCM/WPM 2x500 Weld Planishing Machine is a precision-engineered horizontal 2-roll system designed for stainless steel sheet processing. Built for accuracy and consistency, this PLC-controlled machine ensures smooth and flawless surface finishing after welding operations. With a working length of 500 mm and the ability to handle materials up to 2 mm thick (SS304 and higher grades), it delivers excellent performance for high-quality fabrication tasks.

Powered by a 1 HP main motor paired with a double reduction worm gearbox and supported by a 1 HP hydraulic power pack, this machine offers reliable and efficient operation. It integrates top-grade hydraulic components from Poly Hydron and Yuken, ensuring durability and precision in every cycle.

User convenience is enhanced through a push-button control panel with pedal operation, manual sheet feeding, and hydraulic top roller movement. With a sturdy design measuring 1800×1000×1500 mm, the VCM/WPM 2x500 provides stability, efficiency, and long-term reliability — making it a trusted choice for industrial welding and sheet finishing applications. As a leading Weld Planishing Machine manufacturer and supplier in Coimbatore, India, we deliver machines engineered for performance, precision, and productivity.

| Weld Planishing Machine | ||

|---|---|---|

| SPECIFICATION | REMARKS | |

| Model No. | VCM / WPM 2x500 | |

| Version | 2-Roll | |

| Type | Horizontal - PLC Controlled | |

| Machine Dimensions (L×B×H) | 1800mm × 1000mm × 1500mm (Exact size will be finalized after foundation layout) |

|

| Working Length | 500mm | |

| Minimum Diameter | 100mm | |

| Maximum Thickness | 2mm SS304 & higher grades only | |

| Top Roller | Custom as per product drawing | |

| Main Drive | 1 HP Motor with Double Reduction Worm Gearbox | |

| Hydraulic Power Pack | 1 HP | |

| Hydraulic Valves |

Pressure Relief Valve – Poly Hydron Check Valve – Poly Hydron Solenoid Valve – Yuken Flow Control Valve – Yuken |

|

| Power Supply | 415V, 3 Phase, 50 Hz, 4-Wire System | |

| Travel Speed | Fixed | |

| Electrical Parts | Siemens / L&T Make | |

| Safety Sensors | Included; Sensor Wiring in Client’s Scope | |

| Planishing Cylinder | Hydraulic / 2 Ton | |

| Sheet Feeding | Manual | |

| Component Remover | Manual | |

| Hydraulic Tank Capacity | 25 Litres | |

| Rolling Operation | Bottom roller fixed; Top roller moves hydraulically With Linear Operation | |

| Control Panel | Push Button Switches with Pedal Operation | |

| Approx. Machine Weight | 180 Kg | |

| Component Cycle Time | Approx. 15–25 seconds depending on length and thickness | |