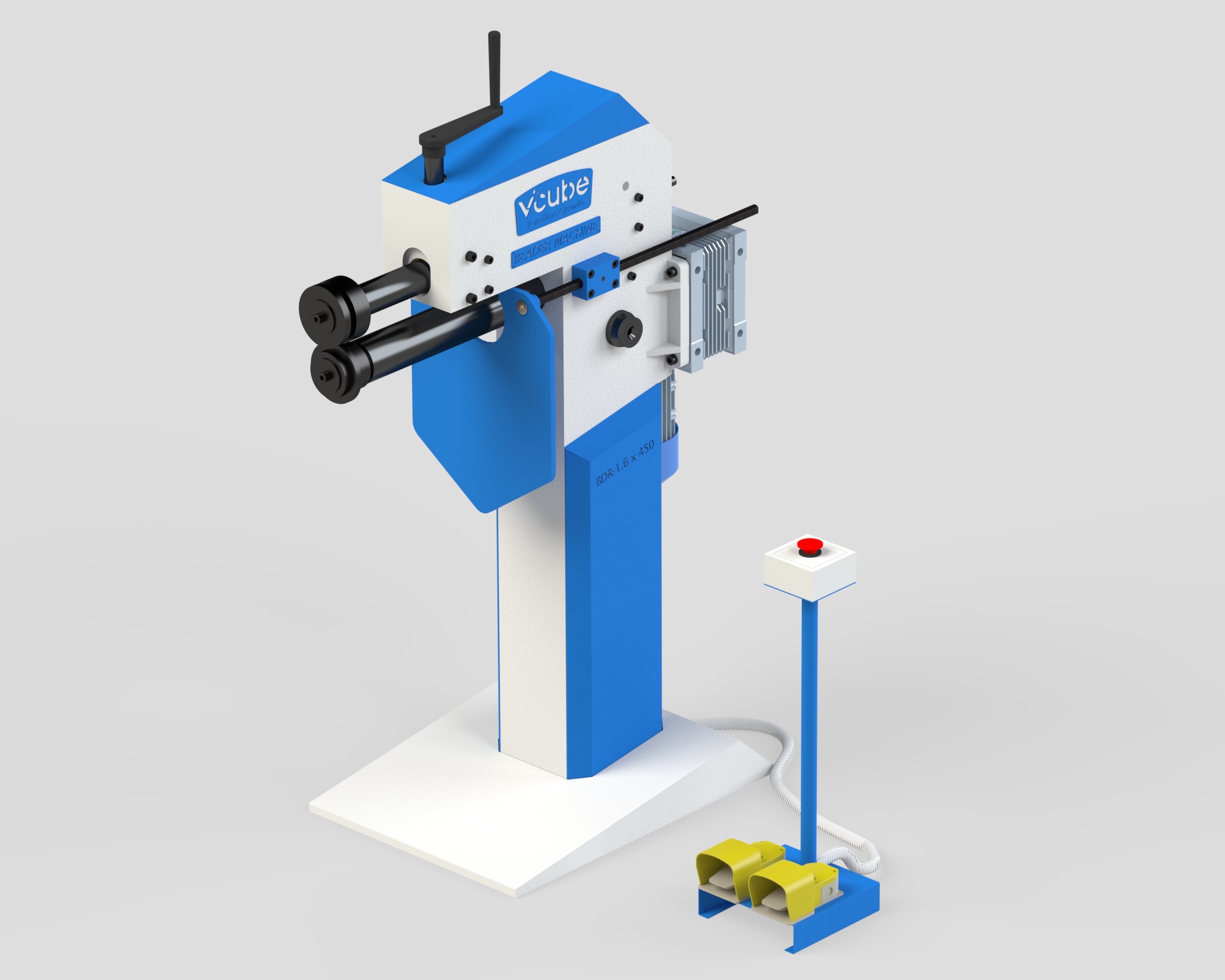

Beader Machine

The VCM BR/1.6x400 Beader Machine is a compact, efficient, and high-precision solution designed for accurate bead formation on metal sheets and pipes. Built with a 1 HP, 1440 RPM motor and a worm gearbox, it ensures smooth operation, controlled performance, and long-lasting durability. Engineered for productivity, this machine delivers consistent bead quality across various materials, making it ideal for industrial workshops and fabrication units.

Its compact structure, measuring 900×600×1000 mm and weighing 275 kg, offers excellent space efficiency without compromising performance. The machine’s sturdy construction and reliable torque output provide precise control, enabling uniform and repeatable bead patterns for enhanced product strength and finish.

As a trusted Beader Machine manufacturer and supplier in Coimbatore, India, we deliver equipment built for speed, precision, and operational reliability. The VCM BR/1.6x400 is the perfect choice for small to medium-scale industries looking to improve metal forming efficiency and overall production quality.

| Beader Machine | ||

|---|---|---|

| SPECIFICATION | REMARKS | |

| Model No. | VCM BR/1.6x400 | |

| Version | 2-Roll | |

| Type | Vertical - Manual | |

| Machine Dimensions (L×B×H) | 1200mm × 500mm × 1200mm (Exact size will be finalized after foundation layout) |

|

| Working Depth | 400mm | |

| Minimum Bending Diameter | 60mm | |

| Maximum Thickness | 1.6 mm ms & higher grades only | |

| Top Roller | Custom as per product drawing | |

| Bottom Roller | 50mm EN8 Shaft | |

| Main Drive | 1 HP Motor with Worm GearBox | |

| Power Supply | 415V, 3 Phase, 50 Hz, 4-Wire System | |

| Rolling Speed | Fixed | |

| Electrical Parts | Siemens / L&T Make | |

| Safety Sensors | Included; Sensor Wiring in Client’s Scope | |

| End Dropper | Manual | |

| Sheet Feeding | Manual | |

| Component Remover | Manual | |

| Rolling Operation | Bottom roller fixed; Top roller moves Manually | |

| Control Panel | Push Button Switches with Pedal Operation | |

| Approx. Machine Weight | 120 Kg | |

| Component Cycle Time | Approx. 40–60 seconds depending on length and thickness | |