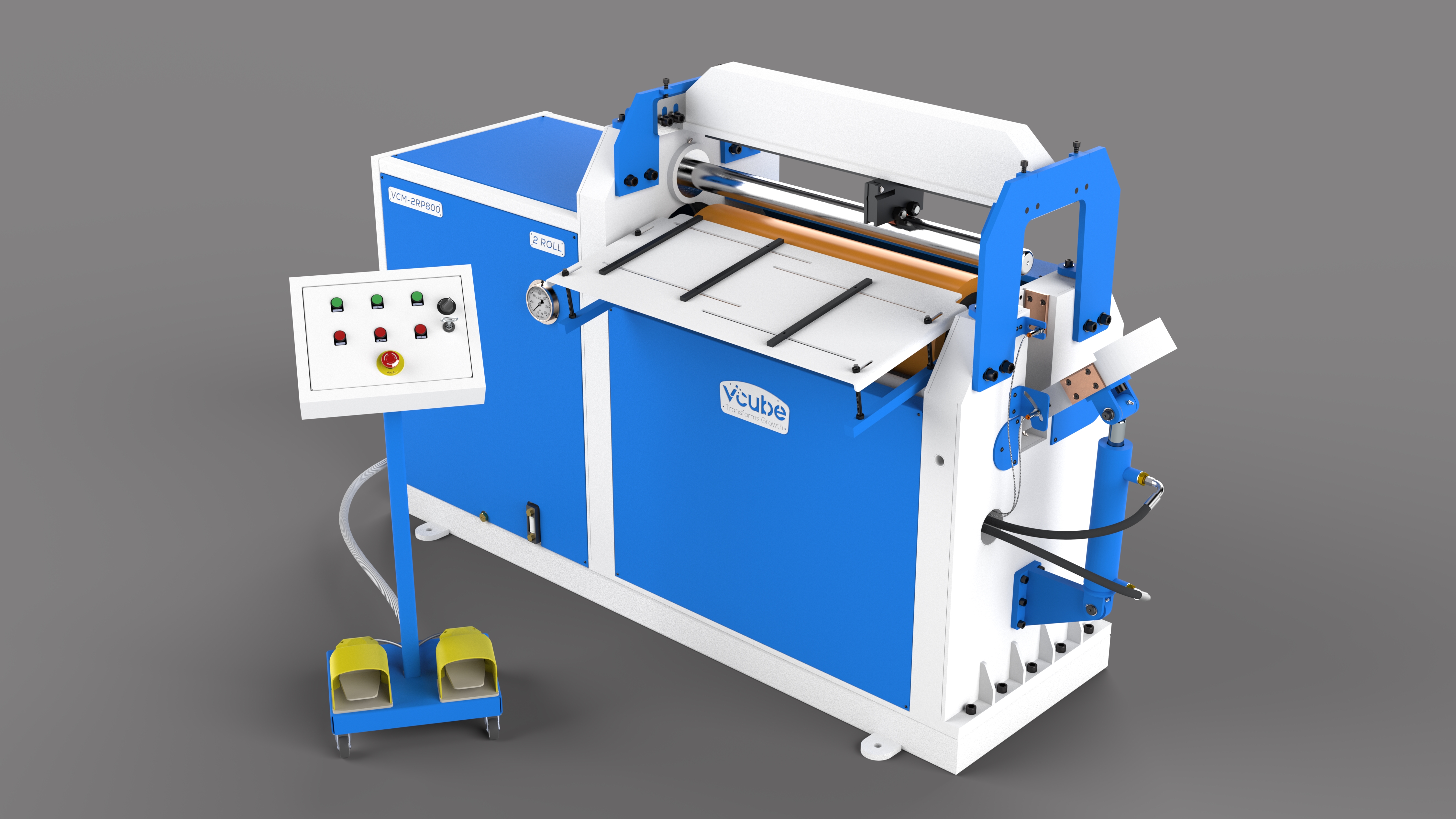

Sheet Rooll Machine VCM/2RHP80

The VCM/2RHP80 Sheet Rolling Machine is a high-performance industrial solution designed for superior accuracy, durability, and smooth sheet forming operations. Engineered with advanced Total Quality Management (TQM) principles, this model ensures consistent rolling precision, improved efficiency, and long-term reliability in production environments.

Built for strength and control, the VCM/2RHP80 guarantees uniform rolling thickness, excellent surface finish, and optimized performance across various industrial applications. Its robust design and efficient motor system make it ideal for industries seeking precision sheet rolling solutions that combine quality and productivity.

As a trusted sheet rolling machine manufacturer and supplier in Coimbatore, India, we focus on delivering equipment that enhances process control, minimizes material waste, and supports continuous production excellence.

| 2-Roll Sheet Roiling Machine | ||

|---|---|---|

| SPECIFICATION | REMARKS | |

| Model No. | VCM/2RHP80 | |

| Version | 2-Roll | |

| Type | Horizontal - PLC Controlled | |

| Machine Dimensions (L×B×H) | 1600mm × 1200mm × 1500mm (Exact size will be finalized after foundation layout) |

|

| Working Length | 800mm | |

| Minimum Bending Diameter | 120mm | |

| Maximum Thickness | 2mm SS304 & higher grades only | |

| Top Roller | Custom as per product drawing | |

| Bottom Roller | 280mm EN8 Shaft with 35mm thick Polyurethane Rubber | |

| Main Drive | 5.0 HP Motor with Inline Helical Gearbox | |

| Hydraulic Power Pack | 3.0 HP | |

| Hydraulic Valves |

Pressure Relief Valve – Poly Hydron Check Valve – Poly Hydron Solenoid Valve – Yuken Flow Control Valve – Yuken |

|

| Power Supply | 415V, 3 Phase, 50 Hz, 4-Wire System | |

| Rolling Speed | Adjustable with VFD Support | |

| Electrical Parts | Siemens / L&T Make | |

| Safety Sensors | Included; Sensor Wiring in Client’s Scope | |

| End Dropper | Hydraulic | |

| Sheet Feeding | Manual | |

| Component Remover | Manual | |

| Hydraulic Tank Capacity | 80 Litres | |

| Rolling Operation | Top roller fixed; Bottom roller moves hydraulically | |

| Feeding Table | Movable feeding table included | |

| Control Panel | PLC Program with Pedal Operation | |

| Approx. Machine Weight | 1300 Kg / 1.3 Ton | |

| Component Cycle Time | Approx. 30–35 seconds depending on length and thickness | |